INCREASING THE EFFICIENCY OF YOUR VALVES

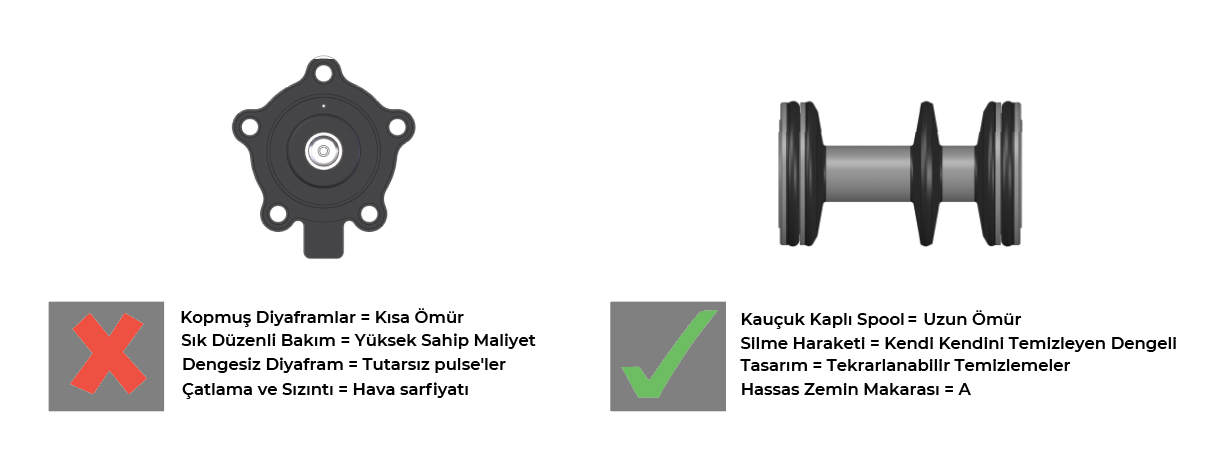

Pulse valves, the new product of MAC Valves, represents a revolutionary advance in pulp engineering. It provides benefits to all companies with bag filters in terms of energy consumption and effective operation.. These valves replace diaphragm pulse valves..

MAC pulse valve represents an important evolution of new generation technology, because it provides superiority to its competitors in all engineering parameters..

Before purchasing another spare part for your diaphragm pulse valves, please pay attention to the following information;

Technology

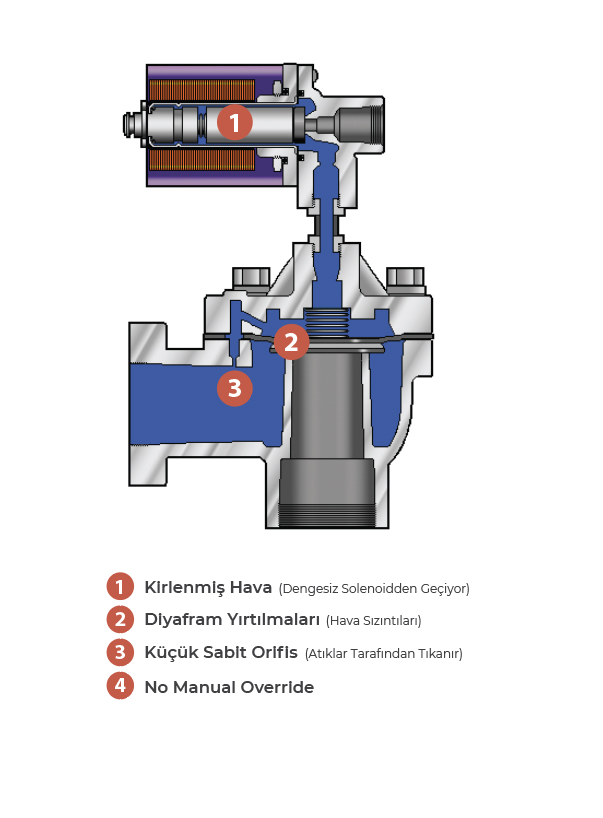

All pulse valves currently on the market, uses diaphragm technology to produce jets of air that clean the filters. The most common brands of these are Goyen, Mecair, IMI Buschjost, Turbo or Asco..

The technology used in existing diaphragm valves is far from being efficient.. Actually, the main element of the diaphragm, as it tends to be subject to small breakouts that cause air leaks, competing valves have always been their weak point.

Membranes over time, They are worn and often fractured as they are subjected to the dynamic forces of air blast. When a diaphragm fails, stays open and allows compressed air to escape continuously, this leads to significant reductions in cylinder pressure and the effectiveness of other valves..

And it also , in this type of valve, solenoid pilots can be blocked, causing the coil to burn.

Failure of thousands of membrane valves in dust collectors is a serious problem for businesses..

Even while reading this text, your compressor likely consumes extra energy to compensate for leaks. Although it is usually obvious from the condition of the valves, this problem, can escape from the attention of the maintenance team due to the noise in the environment and other similar external conditions..

Spool moves with high opening and closing speed, creating a much more effective airflow. In this way, among other benefits, It is possible to reduce the frequency of pulses and therefore the electrical energy consumption associated with them..

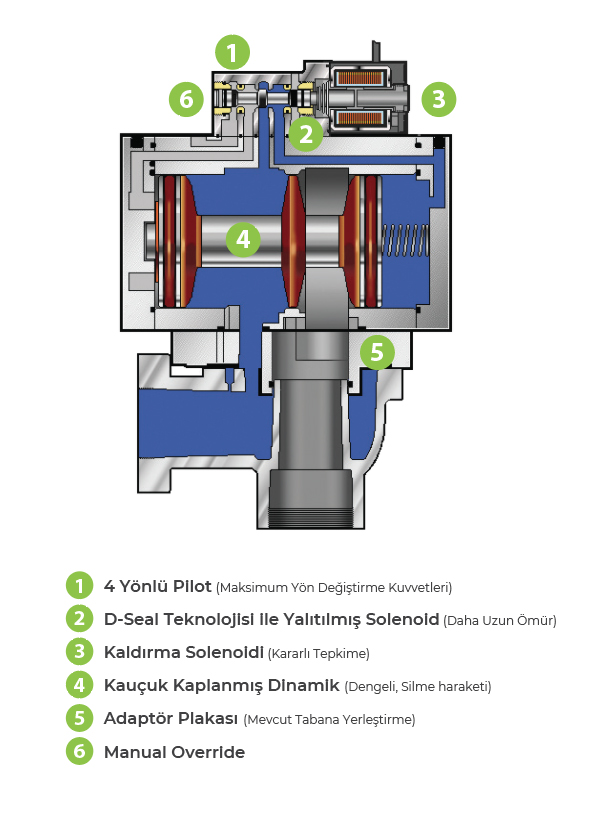

MAC VALVE TECHNOLOGY

OTHER TECHNOLOGIES

gains

MAC design, outperforms diaphragm pulse valve performance in every parameter. MAC pulse valve offers users the advantage of increased valve life. It also eliminates the risk of leakage from ruptured membranes and offers a much wider operating range of temperature and pressure.. Another confirmed result is the increased durability of the filters..

Frequently, from production cuts, Getting rid of high energy costs and increasing the performance of your bag filters are among the benefits of the product..

—

If you prefer the product, You will benefit from improvements in the following points that are important for your industry..

Energy-saving: Thanks to its high firing power, the time required between pulses increases and reduces energy consumption..

Access: Manifold valves are difficult to access. Long durability of the MAC spool valve, reduces safety concerns related to repairs.

Breakdown time: When the bag filter system fails, process must be stopped until it is repaired. Thanks to MAC pulse valve, downtime is greatly reduced.

Product: Weak pulses cause residue to accumulate in the system and problems may occur in removing residues that may contaminate the final product.. MAC pulse minimizes the residue or waste that may occur in your system.

Maintenance costs: Diaphragm valves require constant maintenance. MAC pulse valves, Allows better use of maintenance department resources.

Longer filter life: More efficient and effective pulses, keeps cartridges and filters cleaner, thus extending their lifetime and reducing costs.

Ease of Use: It provides ease of installation as it can be easily adapted to your existing system..

Results

In visuals, You can see results in a real setup where one of the competing valves is replaced by one of the new technology equipped MAC Valves. Bag filter performance has increased from the first pulse..

Picture above, shows a dust collector where one of the valves fails and one of the filters is clogged. You can easily see what.

in the image, You can see results in a real setup where one of the competing valves is replaced by one of the new technology equipped MAC Valves.

MAC Valves with its superior technology, The performance of the bag filter has increased since the first pulse..

CONTACT US

Contact our team. We will be happy to provide you with all the information you need to test our product..

if you wish, we can schedule an introductory meeting with one of our engineers to help you significantly reduce your compressed air and energy consumption.